Product Show

Product Category

Contact Information

Contact Phone:

Company Email:

Company Address:

No.10, Wan'an 3rd Road, Shibei District, Qingdao City

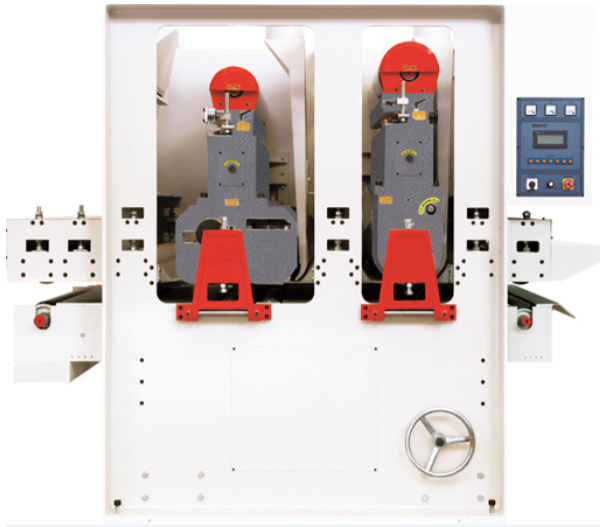

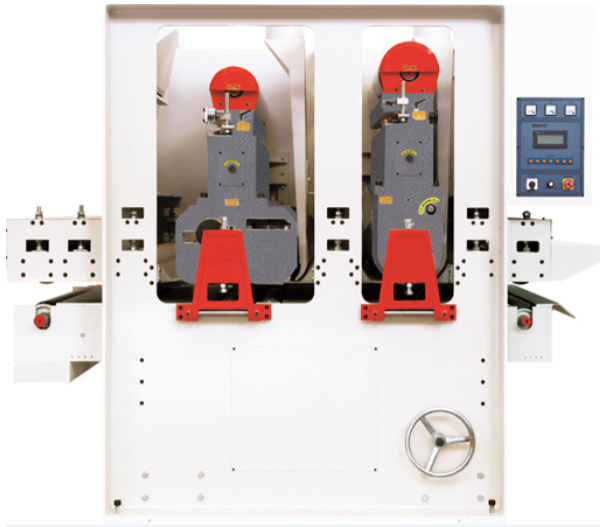

SR2A13-3

Classification:

Eco board fine polishing veneer series sanding machine

Summary:

The company introduces international advanced technology and production inspection equipment. The development and design of products all adopt international advanced three-dimensional (3D) three-dimensional design.

Tel:

The body adopts an integral welded structure and has been aged, with strong rigidity and stable operation.

The sanding roller has undergone accurate dynamic balance detection, and the work is stable and the sanding performance is good.

Frequency conversion feeding, the fastest can reach 100m/min, and the production efficiency is high.

The idler under each sanding head is supported by spring floating, and the back pressure of the workpiece sanding is adjustable, and the sanding quality is high.

The main low-voltage switch parts are Schneider brand products, which are reliable and durable.

Using PLC and touch screen as the main control components, visual operation, fault self-diagnosis, clear entry display, and simple and easy-to-understand text display. The operation is simple, reliable, flexible and durable.

Infrared photoelectric control abrasive belt swing, abrasive belt limit, safe and sensitive.

The inverter is used as the feeding speed regulation, with a wide range of speed regulation, simple and reliable operation, and durable.

Configuration of Model SR2A13-3 Sander

TECHNICAL FEATURES

| Working Width | 40~1300mm |

| Working Thickness | 3~110mm |

| Working Length | ≥750mm |

| No.1 Sanding Belt Speed | 20m/s |

| No.2 Sanding Belt Speed | 17m/s |

| Feeding Speed | 13-100m/min |

| Size of Sanding Belt (W×C) | 1330 x 2615mm |

| Main Motor Power | 37kW,30kW |

| Working Air Pressure | 0.55Mpa |

| Consumption of Compressed Air | 0.1m³/min |

| Volume of Sucked Air | 10000m³/h |

| Speed of Sucked Air | 25~30m/s |

| Overall Dimension (L×W×H) | 2630 x 2960 x 2440mm |

| Net Weight | 7700kg |

Product Series

Customer Message

QingDao QianChuan Woodworking Machinery Co., Ltd.

Copyright©2023 QingDao QianChuan Woodworking Machinery Co., Ltd. Seo