News Center

Groundbreaking! Qianchuan Equipment's new "Piano Key Sander" is now available, opening up a new realm of sanding!!

Release time:

2025-04-15 00:00

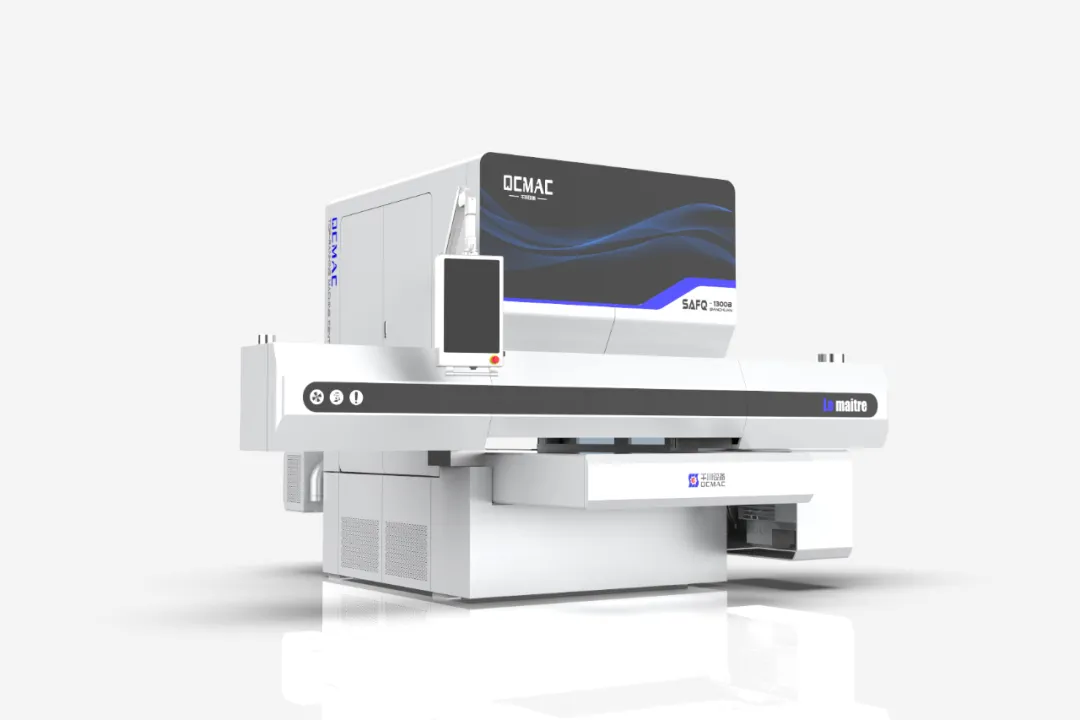

Qianchuan Equipment Brand New "Piano Key Sander"

Grand Launch

Opening a New Realm of Sanding

In the field of woodworking equipment manufacturing, Qingdao Qianchuan Woodworking Equipment Company has always been a pioneer, leading the industry forward. For many years, with its deep technical accumulation and unwavering commitment to quality, Qianchuan has established an excellent reputation in the market. Now, Qianchuan is once again making a strong push, with the grand debut of its carefully developed piano key sander. This new product carries Qianchuan's innovative wisdom and signifies that woodworking sanding technology is about to enter a new stage. How will it subvert tradition and reshape the sanding industry landscape? Let's find out.

Piano Key Sander TVC

Product Features

Flexible Sanding, Adapting to Board Material Characteristics

1. Customizable Sanding Edges: Based on the board material edge detection function, users can avoid sanding the edges of the board, making it more suitable for sanding door panel-type materials.

2. Independent Setting of Sanding Frame Key Block Pressure: The pressure of individual sanding frame key blocks can be set according to the material of the board, the amount of sanding, and the grit of the sandpaper, allowing for a wider range of process parameters.

Precise Control, Ensuring High Efficiency and Stability

1. Precise Conveyor Platform Thickness Setting: Using a servo motor to control the thickness, the floating body design keeps the conveyor platform height unchanged, with thickness setting accurate to 0.01mm.

2. All Sanding Frame Stable Frequency Conversion Speed Regulation: Users can customize the sanding belt speed for more flexible sanding process matching.

3. More Stable Modular Dual-Core Control System: The equipment has separate control systems for the sanding frame and the piano key, which do not interfere with each other, each with its own CPU resources, making program operation faster. High-power remote IO is used, and the safest and most reliable Profinet communication is used, making program data communication more stable.

4. Standardized and Modularized Running Program: For customers with the needs of whole-line networking and MES systems, the program has standardized and modularized data DB, supporting Profinet communication and Modbus-TCP communication, making data interface docking more concise and efficient.

5. Precise Scanning Control System: There are 86 sensors at the infeed end, with a horizontal scanning resolution as low as 16mm. The precise digital array scanning accuracy, timely full-process tracking of sanding operations, and automatic error compensation achieve equal sanding.

Durable Configuration, Improved Processing Quality

1. Stable Conveyor System: Using American Aptco conveyor belts, with aramid tensile layer and rubber wear-resistant material, the service life is 10 times that of ordinary conveyor belts, and the frequency conversion speed control system allows for free switching between different speeds.

2. Fine Sanding Auxiliary Mechanism: A sanding pad buffer device is added to the transverse sanding frame to ensure that the pressure of each sanding key block is consistent, resulting in a more uniform and delicate sanding surface.

3. Non-Contact High-Speed Rotating Wave Plate Surface Dust Removal Device: Using a high-pressure pneumatic 360-degree rotating air knife, with a 20-year ultra-long service life, uniform airflow, an air compression ratio of up to 40:1, and a maximum blowing pressure of 4.0 bar, effectively removing sanding dust from the surface of the board and preventing scratches.

4. Segmented Vacuum Suction Workbench System: The vacuum suction workbench adopts a segmented design, and each vacuum unit is equipped with a separate cast aluminum high-pressure fan, which greatly improves the adsorption force of the board, overcomes board deformation, makes the board perfectly fit the conveyor platform, and prevents board displacement.

Efficiency Revolution, Intelligent Control of the Future!

Qianchuan Piano Key Sander,

Witness the Subversive Moment of Sanding Technology!

Related News

The Advantages and Applications of Floating Sanding Machines in Manufacturing

Floating sanding machines represent a significant advancement in the realm of power tools, particularly within the manufacturing and processing machinery sector. These specialized tools are designed to enhance the efficiency and quality of sanding operations on a variety of surfaces. By utilizing a floating mechanism, these machines provide a unique sanding experience, allowing for uniform pressur

How to Maintain Your Wood Veneer Sanding Equipment for Longevity

How to Maintain Your Wood Veneer Sanding Equipment for Longevity Maintaining your wood veneer sanding equipment is vital to ensure its longevity and optimal performance. Proper care and maintenance not only enhance the efficiency of your equipment but also reduce the risk of costly repairs. In this comprehensive guide, we will delve into effective techniques and practices that can help you extend

Maximizing Efficiency with Floating Thickness Sanding Machines

Floating thickness sanding machines are specialized tools widely used in the manufacturing sector, particularly in the realm of woodworking and material processing. These machines play a crucial role in achieving precise thickness levels on various materials, ensuring that the finished product meets stringent industry standards. One of the primary advantages of floating thickness sanding machines

QingDao QianChuan Woodworking Machinery Co., Ltd.

Copyright©2023 QingDao QianChuan Woodworking Machinery Co., Ltd. Seo