Product Show

Product Category

Contact Information

Contact Phone:

Company Email:

Company Address:

No.10, Wan'an 3rd Road, Shibei District, Qingdao City

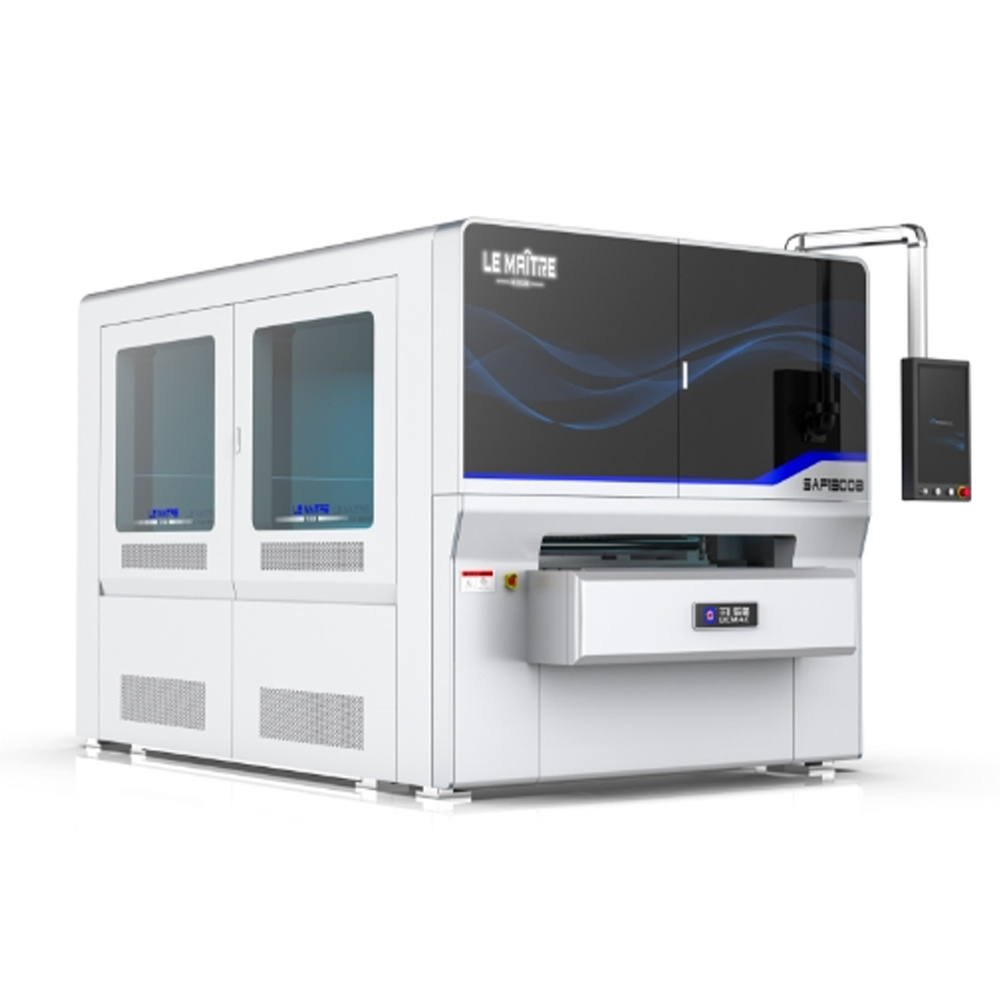

SAF1600A-1

Classification:

Piano Key Series Sander

Summary:

The company introduces international advanced technology and production inspection equipment. The development and design of products all adopt international advanced three-dimensional (3D) three-dimensional design.

Tel:

● The conveying section features an automatic floating function, effectively protecting the workpiece from impact caused by excessive thickness.

● Equipped with an automatic compensation function, with a maximum compensation thickness of 1 millimeter.

● The overall frame is welded using profiled materials and undergoes artificial aging treatment, ensuring that the machine body is resistant to deformation and operates more firmly, smoothly, and reliably. The structure is aesthetically pleasing, elegant, and exudes a high-quality texture.

● A servo motor is used, enabling lifting and lowering with an accuracy of 0.01 millimeters—comparable to the precision of metalworking machine tools.

● Equipped with a central information processing system, it features independent calibration and control for each proportional solenoid valve, ensuring uniform sanding pressure and special edge-and-corner protection. This enables even sanding of boards with uneven thicknesses.

● An sensor is installed at the feed end, reducing the scanning pitch to 16 millimeters for more precise control of scanning accuracy.

● Large-scale PLC with professional proportional amplification module control

● Electromagnetic proximity sensors ensure stable operation of the equipment.

● Custom-designed proportional solenoid touch-screen control and computing integrated unit

Structural Configuration Diagram of Model SAF1600A-1

SAF1600A-1 This type is suitable for veneering artificial boards and primers such as PV, PU, PE, and melamine. It is used for sanding the topcoat, delivering a highly refined sanding finish on the sanded surface.

Technical Parameters

| Workpiece being processed | Thickness | 3-110mm | Brushing roller | 0.37 | |

| Length | >280mm | High-pressure fan | 7.5 | ||

| Width | 60-1600mm | ||||

| Sandbelt | 1# Longitudinal belt speed | 4-12m/s | Compressed air | Work pressure | 0.55mpa |

| 2# Longitudinal Belt Speed | 4-13m/s | Consumption | 1.5 m³/min | ||

| Longitudinal lining bag | 1650x1700mm | Optional dust removal device | Air volume | 16,000 m³/h | |

| Static pressure | 1600Pa | ||||

| Dimensions (width × circumference) | 1630x2620mm | Average wind speed in the pipeline | 20-25m/s | ||

| Conveyor belt | Dimensions (width × circumference) | 1600x5000mm | SAF1600A-1 Technical Specifications | ||

| Conveying speed | 7-20m/min | ||||

| Motor power (kW) | 1# Longitudinal sand frame | 18.5 | |||

| 2# Longitudinal Sand Rack | 18.5 | ||||

| Conveying device | 4 | ||||

| Polishing wheel | 4 | ||||

| Conveyor bed lifting and lowering transmission | 0.75 | ||||

Product Series

Customer Message

QingDao QianChuan Woodworking Machinery Co., Ltd.

Copyright©2023 QingDao QianChuan Woodworking Machinery Co., Ltd. Seo